Umgangatho wokusika i-bevel umisela ukuba i-workpiece inokudityaniswa ngokuqinileyo.Iibevels zokusika isinyithi zemveli zenziwa ikakhulu ngokujika, ukucwangcisa, ukugaya, ukugaya kunye nezinye iindlela.Umsebenzi osikiweyo uneempawu zokusika ezinzulu, i-thermal deformation enkulu, i-gap enkulu kunye ne-arc angle engekhoyo.Ukucutshungulwa kamva kokudibanisa kunzima.Kwaye inkqubo yemveli iyadinwa, ukusebenza kakuhle kwemveliso ephantsi, ayinakuhlangabezana neemfuno zokusika i-bevel ephezulu.Ukusetyenziswa kwezixhobo zokusika i-laser ezine-dimensional-five-axis kuzise impumelelo enkulu ekusetyenzweni kwamalungu esinyithi, ukuhlangabezana ngcono neemfuno zokusika iinqanawa, i-aerospace, ukuveliswa kweemoto, oomatshini bobunjineli kunye nezinye iindawo ezixhasayo ezinemigangatho emithathu.Inkqubo ye-grooving ilandelayo.

1. Ipleyiti eshinyeneyo bevel esebenzayo ukusika

I-Grooving isekela ukusika iipleyiti zetsimbi ukuya kuthi ga kwi-30mm ubukhulu;I-laser yokusika ipleyiti yegroove xa kuthelekiswa nenkqubo yepleyiti yegroove yesiko, ubukhulu buyanda kakhulu, kunceda iinkampani ukuba zandise uluhlu lokusetyenzwa kunye neemeko zesicelo, kwaye ziphucule kakhulu ukusebenza kakuhle kwemveliso.

2. Imveliso ezinzileyo kunye nokulungiswa kwebhetshi

I-grooves yokusika yendabuko ichaphazeleka lula yimiba yangaphandle, ebangela inkqubo yokusika engazinzanga kunye nomgangatho ongalinganiyo weendawo ezicutshungulwayo, ezikhokelela kwimveliso ephantsi;ukusebenzisa izixhobo ze-laser zokusika i-bevel kunokuqinisekisa ngokufanelekileyo ukuchaneka kokusika, umgangatho wokusika ozinzile kunye nokunciphisa iimpazamo zokucubungula.Ifanelekile ukuqhutyelwa kwebhetshi yamacandelo e-groove.

3. Inkxaso yokusika i-multi-slot

Intloko yokusika i-laser ene-dimensional five-dimensional five-axis inokulawula ngokuchanekileyo i-axis yezixhobo ngokobunzima bezinto ezahlukeneyo kunye neemfuno ze-welding, iqhekeza indlela yesiqhelo yokusika, ixhasa i-K, V, Y, U, X kunye nezinye iintlobo zokusika i-Slotting. , ukugcinwa kweenkqubo zokuvelisa, ukusika i-zero-gap ukunciphisa ubunzima be-welding kunye nokuphucula ukusebenza kakuhle kwe-sheet metal processing.

4. Ukuphucula umgangatho we-grooving

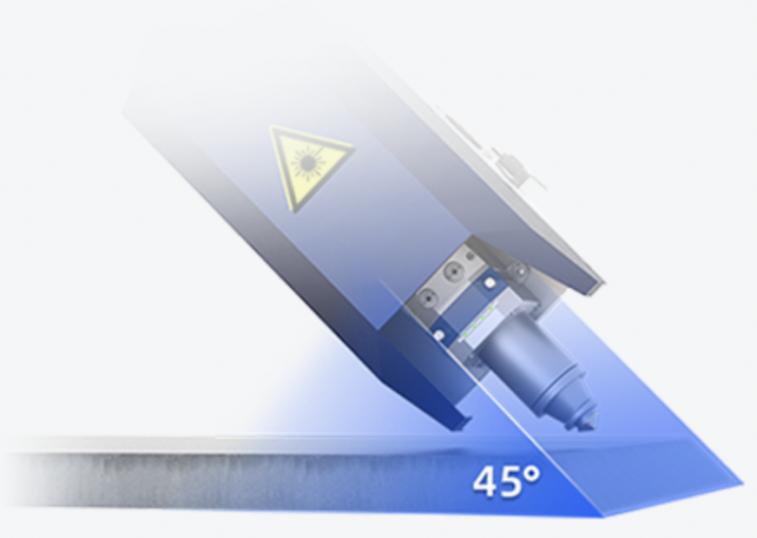

I-3D ye-laser ye-5-axis ye-laser yokusika intloko, inokusika kwaye inciphise umphezulu we-3D we-workpiece;inkxaso ubuninzi 45 ° grooving ngexesha elinye ukwenza, akukho processing yesibini.I-workpiece ingasetyenziselwa ngokuthe ngqo ukuwelda, ngokufanelekileyo endaweni yemveli yokutshiza kunye nenkqubo yokulungisa, ukunciphisa umjikelo wemveliso kunye nokunciphisa iindleko zokuvelisa.

5. Ukunciphisa iindleko zokusetyenzwa kwe-groove

Ukusetyenzwa kweengxenye zegroove yemveli kufuna inxaxheba eninzi yezandla kwinkqubo yokusika kunye nokupolisha;ukusebenzisa izixhobo ze-laser zokusika kunokunceda amashishini anciphise ngokufanelekileyo iindleko zabasebenzi kunye nexesha lokutyalomali, ukusombulula ngokufanelekileyo ingxaki yokuqashwa okunzima kunye nokugcina iindleko zokuvelisa.

Ixesha lokuposa: Dec-27-2022