Hunhu hwekucheka bevel hunosarudza kana workpiece inogona kusungirirwa zvakasimba.Traditional simbi yekucheka bevels anonyanya kugadzirwa nekutendeuka, kuronga, kugaya, kugaya nedzimwe nzira.Iyo yakachekwa workpiece inowanzo ine yakadzika yekucheka mamaki, hombe yemafuta deformation, hombe gap uye inoshaikwa arc angle.Iyo yakazotevera splicing processing yakaoma.Uye maitiro echinyakare anonetesa, akaderera kugadzirwa kwekuita, haagone kusangana nezvinodiwa zvepamusoro-vhoriyamu bevel yekucheka.Kushandiswa kweatatu-dimensional shanu-axis laser yekucheka michina yakaunza budiriro huru mukugadzirisa zvikamu zvesimbi, kusangana zvirinani nekucheka kwezvikepe, ndege, kugadzira mota, mainjiniya einjiniya uye zvimwe zvine chekuita nemativi matatu-dimensional zvikamu.Iyo grooving process ndeiyi inotevera.

1. Ndiro yakakora bevel inobudirira kucheka

Grooving inotsigira kucheka mahwendefa esimbi kusvika 30mm gobvu;laser yekucheka groove ndiro kana ichienzaniswa neyechinyakare groove plate process, ukobvu hunowedzera zvakanyanya, zvichibatsira makambani kuwedzera huwandu hwekugadzirisa uye mamiriro ekushandisa, uye zvakanyanya kuvandudza kugadzirwa.

2. Yakagadzikana kugadzirwa uye batch processing

Traditional cutting grooves inobatwa nyore nyore nekunze kwezvinhu, zvichiita kuti kusagadzikana kwekucheka maitiro uye kusaenzana kwehutano hwezvikamu zvakagadziriswa, zvichiita kuti zvive zvishoma;kushandisa laser midziyo yekucheka bevel inogona kunyatso kuve nechokwadi chekucheka chaiko, yakagadzikana yekucheka mhando uye kuderedza zvikanganiso zvekugadzirisa.Inokodzera batch processing yezvikamu zve groove.

3. Tsigira akawanda-slot kucheka

Matatu-dimensional shanu-axis laser yekucheka musoro inogona kunyatso kudzora axis yemidziyo zvichienderana nehupamhi hwezvinhu zvakasiyana-siyana uye welding zvinodiwa, kupaza neyakajairwa mutsara wekucheka nzira, inotsigira K, V, Y, U, X uye mamwe marudzi ekucheka Slotting. , kuchengetedza maitiro ekugadzira, zero-gap kucheka kudzikisa kuoma kwewelding uye kunatsiridza kugona kwepepa simbi kugadzirisa.

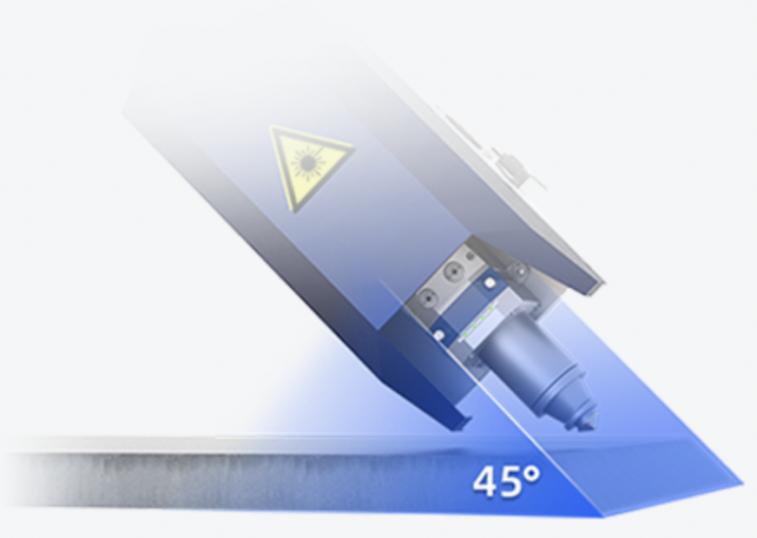

4. Kuvandudza kunaka kwe grooving

3D shanu-axis laser yekucheka musoro, inogona kucheka uye kucheka iyo 3D yakaumbwa pamusoro peiyo workpiece;inotsigira yakakura 45 ° grooving imwe-nguva kuumba, hapana yechipiri kugadzirisa.Iyo workpiece inogona kushandiswa yakananga kukwenenzvera, kunyatso kutsiva yechinyakare kufa punching uye kucheka maitiro, kupfupisa kutenderera kwekugadzira uye kuderedza mutengo wekugadzira.

5. Deredza groove processing cost

Traditional groove parts kugadziridzwa kunoda kuwanda kwebhuku rekutora chikamu mukucheka nekupukuta maitiro;kushandisa laser midziyo yekucheka inogona kubatsira mabhizinesi kunyatso kudzikisa mutengo wevashandi uye nguva yekudyara, kugadzirisa zvinobudirira dambudziko rekuomerwa kwekutora uye kuchengetedza mutengo wekugadzira.

Nguva yekutumira: Zvita-27-2022