Qhov zoo ntawm bevel txiav txiav txim siab seb lub workpiece puas tuaj yeem ruaj khov.Cov tsoos hlau txiav bevels yog tsim los ntawm kev tig, kev npaj, milling, sib tsoo thiab lwm txoj kev.Kev txiav workpiece feem ntau muaj cov cim sib sib zog nqus, thermal deformation loj, qhov sib txawv loj thiab tsis muaj lub kaum sab xis.Tom qab splicing ua yog nyuaj.Thiab cov txheej txheem ib txwm yog tedious, tsis tshua muaj kev ua tau zoo, tsis tuaj yeem ua tau raws li qhov yuav tsum tau muaj ntawm high-volume bevel txiav.Daim ntawv thov ntawm peb-dimensional tsib-axis laser txiav cov cuab yeej tau ua rau muaj kev cuam tshuam loj hauv cov khoom siv hlau, ua kom tau raws li cov kev xav tau ntawm cov nkoj, aerospace, tsheb tsim, engineering machinery thiab lwm yam kev txhawb nqa peb-dimensional qhov chaw.Cov txheej txheem grooving yog raws li nram no.

1. Thick phaj bevel npaum txiav

Grooving txhawb txiav cov hlau phaj mus txog 30mm tuab;laser txiav groove phaj piv nrog cov txheej txheem groove phaj, lub thickness nce ntau, pab cov tuam txhab kom nthuav dav kev ua haujlwm thiab daim ntawv thov scenarios, thiab txhim kho ntau lawm efficiency.

2. ruaj khov ntau lawm thiab batch ua

Cov tsoos txiav grooves tau yooj yim cuam tshuam los ntawm lwm yam, ua rau cov txheej txheem txiav tsis ruaj khov thiab tsis sib xws ntawm cov txheej txheem ua tiav, ua rau cov khoom lag luam qis;siv cov cuab yeej laser rau bevel txiav tuaj yeem ua kom raug txiav, ruaj khov txiav zoo thiab txo cov kev ua yuam kev.Nws yog haum rau batch ua ntawm groove qhov chaw.

3. Txhawb kev txiav ntau qhov

Peb-dimensional tsib-axis laser txiav lub taub hau tuaj yeem tswj cov cuab yeej axis raws li cov tuab ntawm cov khoom sib txawv thiab cov kev xav tau vuam, tawg los ntawm cov qauv kev txiav tawm, txhawb K, V, Y, U, X thiab lwm hom kev txiav Slotting. , txuag cov txheej txheem ntau lawm, xoom-kawg txiav kom txo tau qhov nyuaj ntawm vuam thiab txhim kho cov kev ua haujlwm ntawm cov ntawv hlau.

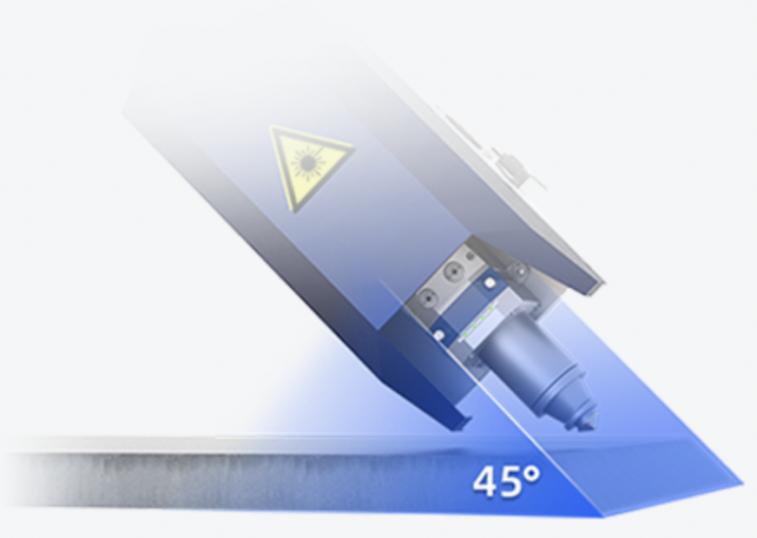

4. Txhim kho qhov zoo ntawm grooving

3D tsib-axis laser txiav lub taub hau, tuaj yeem txiav thiab txiav 3D zoo li tus nto ntawm lub workpiece;txhawb siab tshaj 45 ° grooving ib zaug ua, tsis muaj kev ua haujlwm thib ob.Lub workpiece tuaj yeem siv ncaj qha rau vuam, zoo hloov cov tsoos tuag xuas nrig ntaus thiab trimming txheej txheem, shortening lub voj voog ntau lawm thiab txo cov nqi tsim khoom.

5. Txo cov nqi ua cov zawj

Ib txwm groove qhov kev ua tiav yuav tsum muaj ntau phau ntawv koom nrog hauv kev txiav thiab polishing;siv cov cuab yeej laser rau kev txiav tuaj yeem pab cov tuam txhab lag luam txo cov nqi zog thiab lub sijhawm peev, daws cov teeb meem nyuaj rau kev nrhiav neeg ua haujlwm thiab txuag cov nqi tsim khoom.

Post lub sij hawm: Dec-27-2022