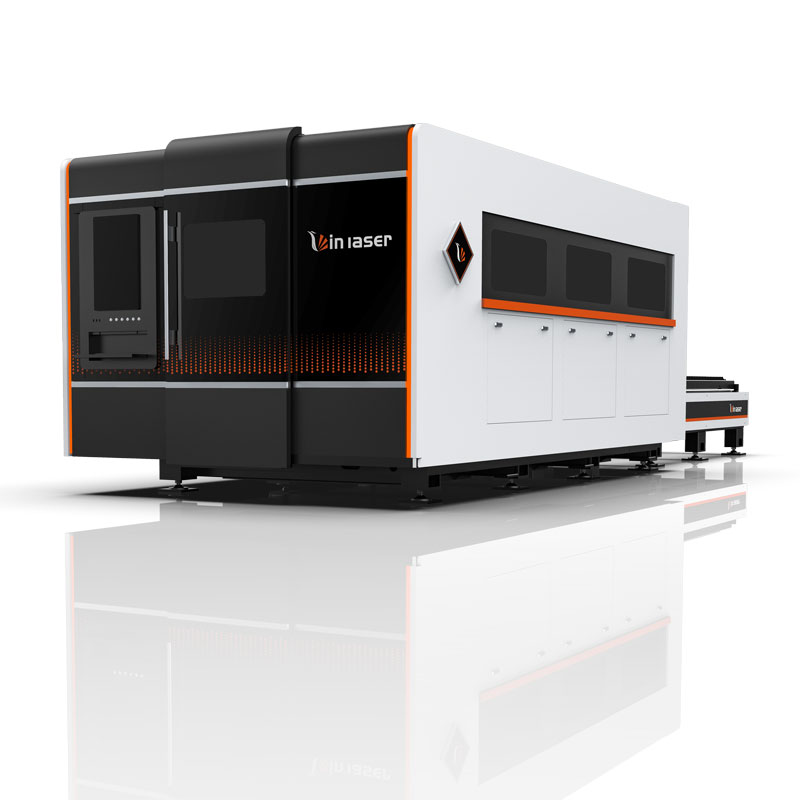

OEM Factory For Tube Cutting - Sheet&Tube Dual-use Fiber Laser Cutting Machine – Lin Laser

OEM Factory For Tube Cutting - Sheet&Tube Dual-use Fiber Laser Cutting Machine – Lin Laser Detail:

Fiber laser cutting machine is mainly used to cut carbon steel, stainless steel, copper, aluminum and other metal materials. It can meet the cutting processing needs of most industries. Because of the small laser spot, high energy density and fast cutting speed, laser cutting can obtain better cutting quality compared with traditional plasma, water jet and flame cutting. At present, laser cutting machine has been widely used in advertising signs, sheet metal processing, solar energy, kitchenware, hardware products, automotive, electrical appliances, precision parts and other industries.

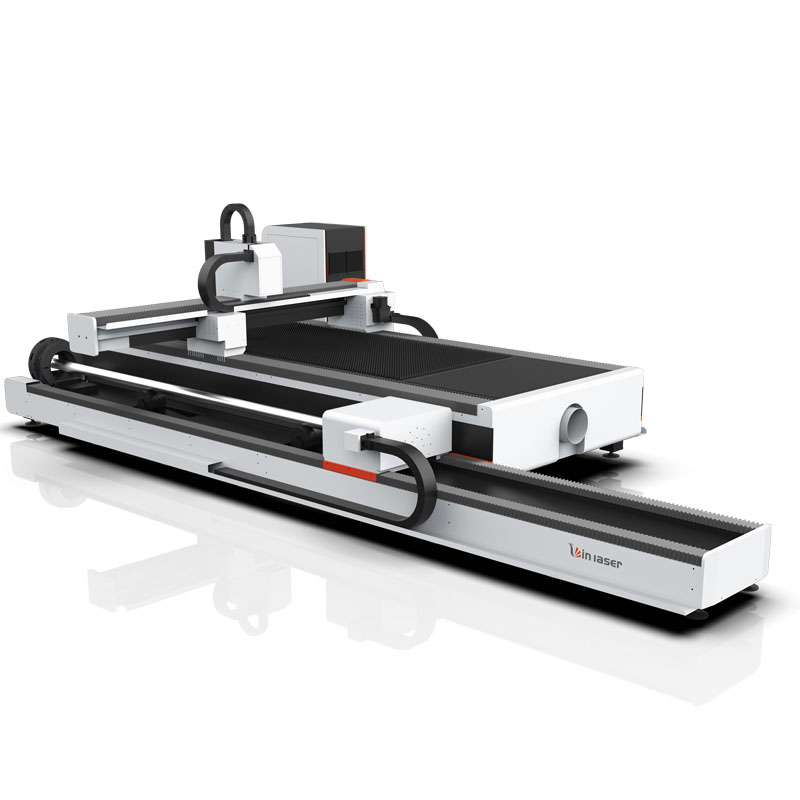

Dual-use sheet and tube

One machine is multi-functional to meet the needs of two kinds of processing.Save more than 50% of space and costs, improve production efficiency.

The newly upgraded second-generation welding bed

Stress annealing treatment is performed to eliminate internal stresses and maintain the extremely high stability and cutting accuracy of the bed.the weld is not easy to crack, and has good tensile performance, toughness and hardness.

Ultra-high stretched aluminum beam

High density, high rigidity and light weight, good dynamic performance, strong deformation resistance, high flexibility, can achieve high-precision positioning and cutting, improve processing efficiency.

Auto Focus Laser Cutting Head

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head

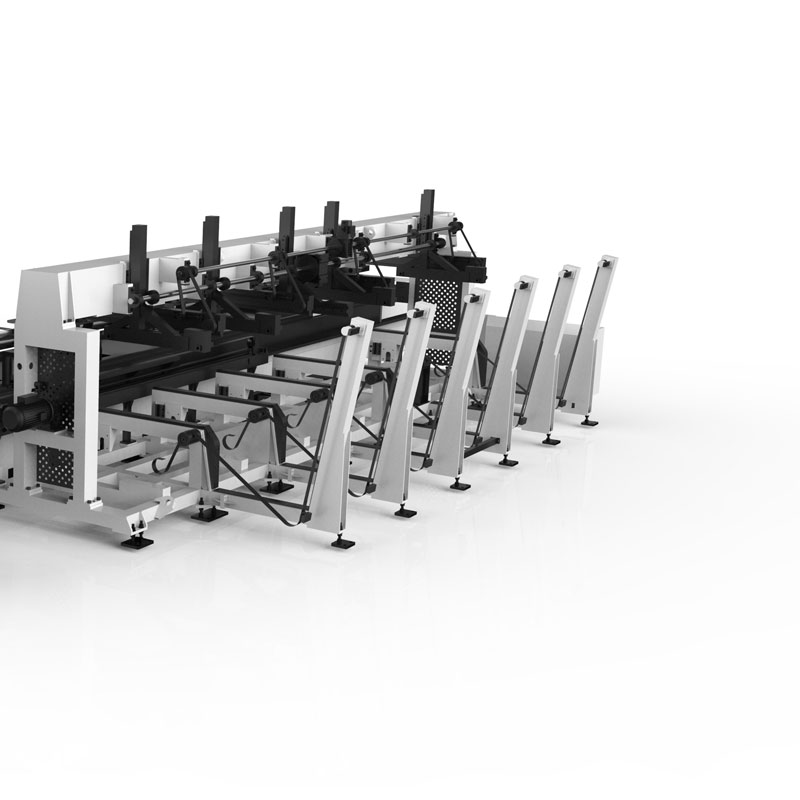

Pneumatic chuck

Front and rear chuck clamping design,one key open clamping, automatic alignment, pneumatic clamping, large clamping force, ensure stable feeding and cutting accuracy, improve processing efficiency.

Wireless controller

It adopts wireless controller, which is easy to control and operate, and can reduce the deformation of pipes. It is easy to operate and control the machine work, such as cutting, moving, piercing, calibrating, emergency stop, etc.

Product Overview

Product detail pictures:

Related Product Guide:

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for OEM Factory For Tube Cutting - Sheet&Tube Dual-use Fiber Laser Cutting Machine – Lin Laser , The product will supply to all over the world, such as: Argentina, Hongkong, Russia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.